Ad Available With Flotation Devices Electric Hoists Traversing Winches More. The series pumps are innovative in hydraulic design structural design and wear-resistant materials.

Tobee Centrifugal Horizontal Slurry Pump Pages 1 6 Flip Pdf Download Fliphtml5

Slurry Pump Box Design.

. Pump boxes or slurry pumps are used across the mining and oil and gas industries. Powerful and efficient mixing power with MAJOR Slurry Pumps. Distribution box or other pressurised vessel m slurry Hd Total pump discharge head referred to pump centreline usually positive m fluid.

The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry similar to how a water-like liquid would move through a standard centrifugal pump. Describe slurry pumps slurry pumping and the various parameters required when selecting submersible slurry pumps using FLYPS. Plugging of pump caused by use of an intake feed passage.

They must also be able to pass large solids. The vertical design of Centrifugal Slurry Pumps shown at the right overcomes such common difficulties as stalling caused by handling difficult slurry containing slurry or coarse material. The utility model has the advantages of high efficiency energy saving small vibration low noise reliable operation long service life and convenient maintenance.

73100_Multotec_Slurry Pumps Brochure V6indd 6 20170815 237 PM Design Characteristics Boost your froth pumping levels with the froth pump that has been designed to ensure high. Specific gravity of liquid different from design Entrained air in pump pump hopper requires baffles. Shell The most efficient design today the pump shell is shaped like a nautilus seashell and surrounds the impeller.

To provide a deeper understanding of the calculations a manual calculation example is given in the appen-dix of the book. They separate out oversized solids to create a slurry. The packing area of stuffing box is longer than expeller ring so it can contain more packing.

Compared with conventional water pumps the above requirements result in a larger pump that is less. First of all slurry pumps should be designed for specific operating requirements. Improper suction system design may result in surging of the pump flow air locking or cavitation any of which may prevent the slurry pump from operating as designed.

Its job is to take the flow from the impeller and direct the slurry into the pump discharge. Slurry pump stuffing box is one of shaft seal parts in gland packing seal pumps where the packing is housed in. The reason for this occurrence are the specific characteristics of the slurry moving through the system.

If the slurry does not present problems not as much care in design is required therefore the. Slurry pump box design Valentines Working day is approaching it is simply per month away but There are tons of things to get ready from dresses to your ingesting spot from bouquets on the presents baskets We have now to rearrange almost everything for our family members. Hydraulic Design of a Slurry Distribution Box 21.

If you are not sure about the type of slurry the choice of pump the design of the pipe system. Diverter box design for mixing slurry and top filling keeping fuel costs to a minimum. Drop boxes are used as devices to convey a slurry from one elevation to another vertically considerations in design of drop boxes include inlet diameter height outlet and wear for a given flow.

The suction sump takes feed from. A slurry pump is a centrifugal type specifically designed for hydraulic conveyancing of abrasive and often corrosive solid particles within a carrier fluid. Distribution boxes are designed with a number of chambers and hydraulic controls to ensure thorough mixing of the incoming slurry streams and even distribution to each outlet of volumetric flow rate solids concentration and particle size while maintaining stable flow.

And air locking caused by intermittent feed or the handling of air laden slurry. SECTION 11 Examples of Slurry Pumps and Pipelines 39 APPENDIX 1 Diagrams for Slurry Pumping. For this discussion the suction system is split into two primary design areas.

Clean water is injected into the stuffing box to flush solid particles away and to cool and lubricate the packing and shaft sleeve. ZJ Series Slurry Pump are a new high-efficiency energy-saving anti-wear pump. They must be able to pump high-density abrasive slurries while maintaining reasonable wear life.

Proudly Manufacturing Industrial Pumps Systems Since 1961. Wear considerations affect the previous parameters. While doing this it also slows the slurry flow velocity and increases its pressure turning kinetic energy into pressure energy.

73100_Multotec_Slurry Pumps Brochure V6indd 6 20170815 237 PM Design Characteristics Boost your froth pumping levels with the froth pump. Slurry wears packing Slurry wears shaft sleeve. Air leaks into pump through stuffing box Inlet of suction pipe insufficiently submerged Blocked suction line.

This ensures your materials can be transported through pipelines to their end destination. Ad Find Deals on slurry pump in Home Improvement on Amazon. As with many industrial machines slurry pumps are susceptible to wear-and-tear over time.

Our pump boxes can be customized to handle any project regardless of size or scope. The slurry pump should be of a low specific speed design allowing slower operating speeds than conventional water pumps in order to reduce the velocity of the solid particles and thereby. Basic Guidelines for Design of Slurry Mixing Agitators.

The sump and the piping. SECTION 9 Pump Design and Selection. Available in 7ft and 8ft lengths 3pt linkage fully galvanised body and frame.

Pump boxes or slurry pumps are used across the mining and oil and gas industries. Many types of pumps are used for pumping slurries but the most common slurry pump is the centrifugal pump. Depending on the abrasiveness and corrosiveness of your slurry the pump can begin wearing down in a matter of days.

Hydraulic Design of a Slurry Distribution Box 21. To prevent solids from settling the sump should be built with sloped walls at or exceeding the slurrys angle of repose when it begins sliding. The major technological facilities for Alumina Refinery comprises of various types of stationery and rotating process equipment like.

We find that 30 is generally the shallowest angle that can be effective but this needs to be tailored to your sump your slurrys characteristics and the circuits pressure.

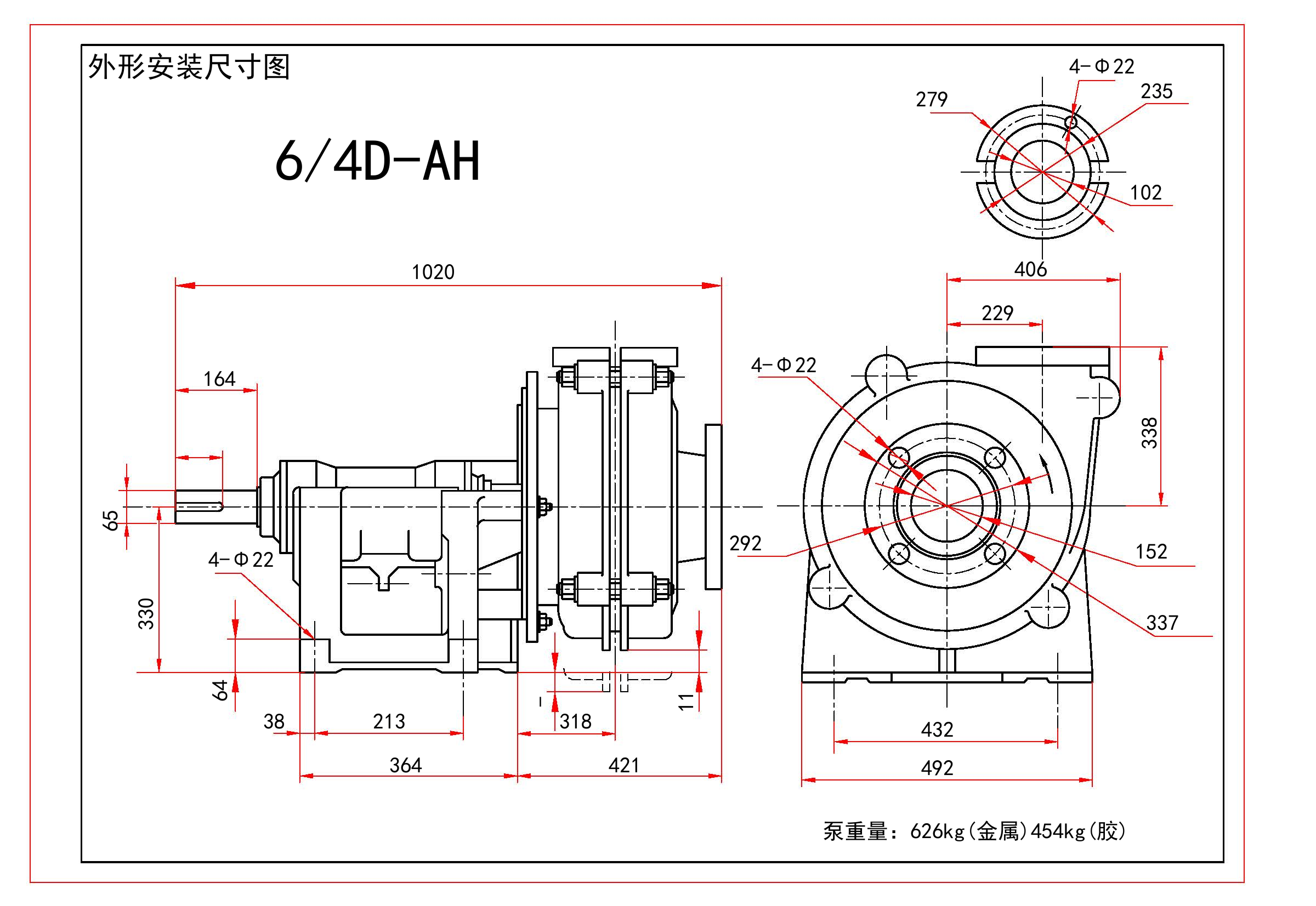

China 6 4d Ah Heavy Duty Slurry Pump Kualitas Tinggi 6 4d Ah Heavy Duty Slurry Pump Di Bossgoo Com

Ah R Hh M R Series Slurry Pump Innovomax

New Pump Box For Sale By Savona Equipment

3d Printed Slurry Pump Box By Neko Rodrigues Pinshape

New Pump Box For Sale By Savona Equipment

Top 10 Slurry Pump Feed Tank Suction Pipe Design Recommendations

0 komentar

Posting Komentar